.jpg)

with canias4.0... Preparation for the Lights-out Factory Era Has Begun!

Global technology company Industrial Application Software (IAS) has recently been on top of the agenda with its successful projects. The company, which recently announced its South Korean operations and business partnership with Hyundai AutoEver, is also increasing its momentum of success with the studies they carry out in Türkiye. IAS recently reported that canias4.0 technology will be used in model factories in various cities of Türkiye. We have come together with Yaşar Hakan Karabiber, the Chairman of the Board of Directors of the company and asked him about sustainability, future visions and the recent developments in IAS.

canias4.0 Technology Will Be Used in Model Factories

Particularly, a model factory project for the dissemination of the operational excellence principles of SMEs is on your agenda. Can you tell us about this project?

The Applied SME Competence Center (Model Factory) was established in cooperation with the Ministry of Science, Industry and Technology- General Directorate of Productivity and the United Nations Development Program (UNDP). Model Factories were built on the purpose of disseminating the principles of operational excellence in enterprises to increase scalability in companies by using experiential learning techniques and particularly to include SMEs in the digital transformation process by training them in this direction. Now, canias4.0 technology will start to be used in model factories located in various cities of Türkiye. In other words, there will be IAS the technology guide and the technologies IAS offers with the canias4.0 in Model Factories. As IAS, we will provide integrated and standardized solutions and technological infrastructure (hardware & software) in all selected Model Factories in Kayseri, Ankara, Konya and Bursa with the technologies we offer under the canias4.0 brand. As a company, we are changing the traditional and integration-based communication architecture with the technologies and products we have developed. We minimize the energy that users will spend to use and maintain the systems with the integrated systems we offer. We will enable SMEs in our country to experience and learn the service we offer to our customers worldwide with our MES and IoT products that work as integrated and synchronized with ERP through Model Factories. Our technology is proven in the projects we have carried out in the countries where digital transformation is at an important and advanced stage such as South Korea and Germany. We are excited to bring together our technology and our sectoral solutions that we have applied in different sectors with SME-level enterprises in our country and add value to them.

Lights-out Factories Will Also Change Social Life

What is the era of Lights-out factories? What advantages does canias4.0 provide to companies in the transition to this period?

Lights-out factories are structures consisting of automated systems that aim to carry out production without the need for human intervention or with minimal human intervention. Today, the increasing trend of automation has gained great speed with the developments in the field of technology. In a short summary, we can say that simple and repetitive processes are carried out by robots and processes that require creativity and foresight are carried out by humans.

What we had to do was to come up with a model for ourselves. The Industry 4.0 concept launched by Germany is being followed in Türkiye. As IAS, we apply our global vision to our projects in Türkiye and support our customers in their competition with global companies. The future, “unfortunately” brings before us different concepts of production that people are moving away from. This situation will cause social problems. For this reason, the countries need to determine policy and take action already now. We believe that the model factory project will be an important start in order to make the transition from smart factories to the Lights-out factories era in our country. We offer solutions with our integrated and synchronized products to the failures caused by the integration problem in the transition from pilot application to the main system which is an important issue in the digital transformation journey of enterprises in the world also.

What benefits will the transition to the Lights-out Factories era bring for management?

Because the production will be carried out entirely by robotic systems in Lights-out factories, it offers stable production output. It increases factory productivity as the rate of defective production will decrease. It will reduce labor costs as it enables production without the need for human intervention or getting the production output with the minimal human intervention will be possible. Since production losses will be minimized when the fixed product output and the energy usage are proportioned, the manufacturing energy per product will also decrease which is the most important factor in the formation of sustainable quality, energy consumption and costs. Digitalization of production management systems will reveal more predictable product, quality and maintenance processes. Therefore, managers will be able to focus on production management, optimizing quality and energy and costs directly, instead of dealing with everyday problems.

We Prepare Companies for the Lights-out Factory Era with canias4.0

What steps are you taking as canias4.0 in the name of sustainability?

As IAS, we continue to our studies by developing and renewing our products and services. For this purpose, we have carried out performance-enhancing studies in all our modules with the awareness that the digital revolution is speed itself and speed means performance. We have made performance monitoring and management tools more effective. We have added many new protocols to the system and developed the infrastructure of machine communication and web services. We have provided integration with artificial intelligence assistants. We showed an increase in speed and flexibility in working on the cloud. We have developed new products such as manufacturing intelligence and canias IQ. We have completed many projects within the scope of the canias4.0 IoT Solution. In the new period, we will continue to be on the agenda with our R&D studies and new projects. We will continue to provide companies with the most suitable products and services for their corporate necessities as well as their needs in Industry 4.0 and digital transformation processes and carry out studies that will steer the sector.

Why/how canias4.0 Technologies offer a competitive advantage to its users?

Our solutions, which we offer under the canias4.0 Technologies brand, exist to standardize the systems of companies. Thanks to canias4.0 technologies, companies are making their business processes much faster, more sustainable and more traceable. With canias4.0, the effort spent for making information access fast is minimized and naturally, the cost is reduced. In this way, companies make much faster decisions and solve the issues in their business at a much lower cost. As a result, they gain a serious advantage in competition. A sustainable system means that repetitive tasks can be done in ERP without errors and independently of the operator. ERP software can ensure that growth is realized in a planned way with a corporate structure and with as many resources as needed. With traceable processes, everyone can see the same data and speak the same language. In this way, the internal coordination of the companies is maximized, the errors are visible and the quality of work and product increases. Our customers are aware of the importance of technology in their production processes and follow a constantly developing trend that invests in this direction. In this process, as IAS, we think that we are a good companion to them with all our technological infrastructure and knowledge. As a company that constantly invests in technology, just as we have supported our customers in the transition to Smart Factories, we will continue to be with them with our technologies in their journey to become a Lights-out Factory.

A New Era Will Begin with IAO

What are your aims for the coming year?

As a global technology company IAS, we aim to be the leading ERP, MES and IoT Company in digital platforms. For this, we are improving our tools and technologies day by day. We carry technology to all corners of the world, including many countries such as South Korea, Germany, Dubai, India and Pakistan and we increase our success in the international market every passing day. In addition, with our Industrial Application Objects (IAO) product in the near future, we will have made our modules the leanest, simplest, most benefit/cost ratio and perfect industrial application object used in industrial environments in the world. The IAO will bring a whole new perspective to the industry.

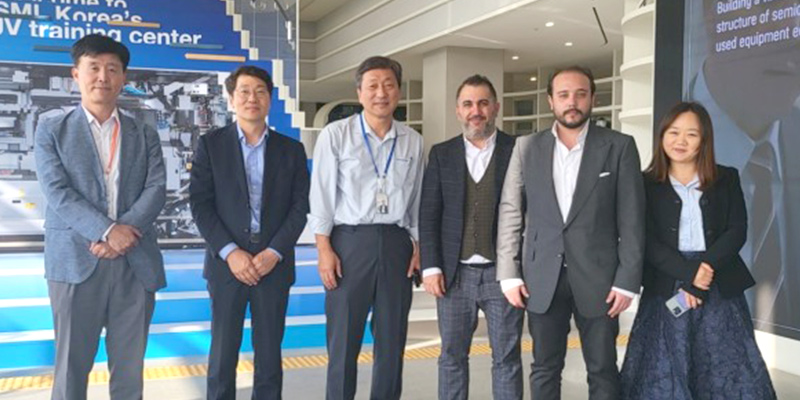

Great Success in South Korea

Can you tell us about the cooperation you started with Hyundai in South Korea?

We recently launched a global partnership with Hyundai AutoEver which provides solutions for all information technology components within the Hyundai Motor Group. The GGM project that we previously carried out with Hyundai Motor Company was completed with great success. South Korea's new generation vehicle Hyundai Casper which is very popular on the country’s agenda was produced using caniasERP. During this project process, our relations with the company were strengthened and they had the chance to closely observe both the quality of the solutions we offer and the principles of our team. They experienced how the easy-to-develop, flexible structure of caniasERP creates added value for them. With the successful completion of the GGM project, we started to talk about new projects that could be realized in the future. The Hyundai Motor Group operates in many different sectors such as shipbuilding, iron/steel industry, hydrogen battery, automobile and construction under its umbrella. With this partnership, caniasERP is now present in all companies and sectors within Hyundai as well as among OEM suppliers in many countries around the world in partnership with Hyundai. It was a proud and exciting development for us to sign such important cooperation in South Korea which is one of the technology centers of the world.